Home Pro

Professional PID (vibratory pump)

Professional PID (rotary pump)

Close/Cerrar

High definition backlit capacitive display. 4.2” LCD screen. Allows total control of all the machine’s parameters in an instant, quickly and intuitively.

The display gives real time feedback on all the operations the machine is performing at any given time. There are several simple, fast and intuitive menus. It’s like using a smartphone! The icon language is instantly familiar.

This is a state-of-the-art product (touchscreen, highly sensitive, tempered glass, anti-knock and anti-scratch surface).

In addition to thermally insulating the coffee groups and the steam boiler, we also cover all the pipes to prevent heat loss and maintain thermal stability throughout the assembly.

Ideal for machines placed on the front bar.

With the Barista logo laser-cut into the rear panel of the machine and backlit by an interior lightbox. A decorative element that takes the machine to another level.

A stronger railing that reinforces the machine's image. Made of stainless steel.

First, society changes. Neither manufacturers nor engineers nor industrial engineers invent new needs. It is society that demands products that are more sustainable with improved energy efficiency, easier to use and longerlasting.

In these new times, it is the professional barista who demands innovative products without compromising the espresso’s.

At Ascaso, our team of engineers has spent years working to differentiate and perfect our espresso coffee machines. And this has led us to reappraise our approach to tradition. To ground our projects on sustainable engineering.

In the ‘60s, the development of the E-61 group brought innovation to the espresso world. It was an instant success and became one of the most widely used systems in the history of espresso coffee Even today, many manufacturers still use it or work with its principles.

But, almost 60 years later, we needed to look for a new technology that addressed the shortcomings of the old.

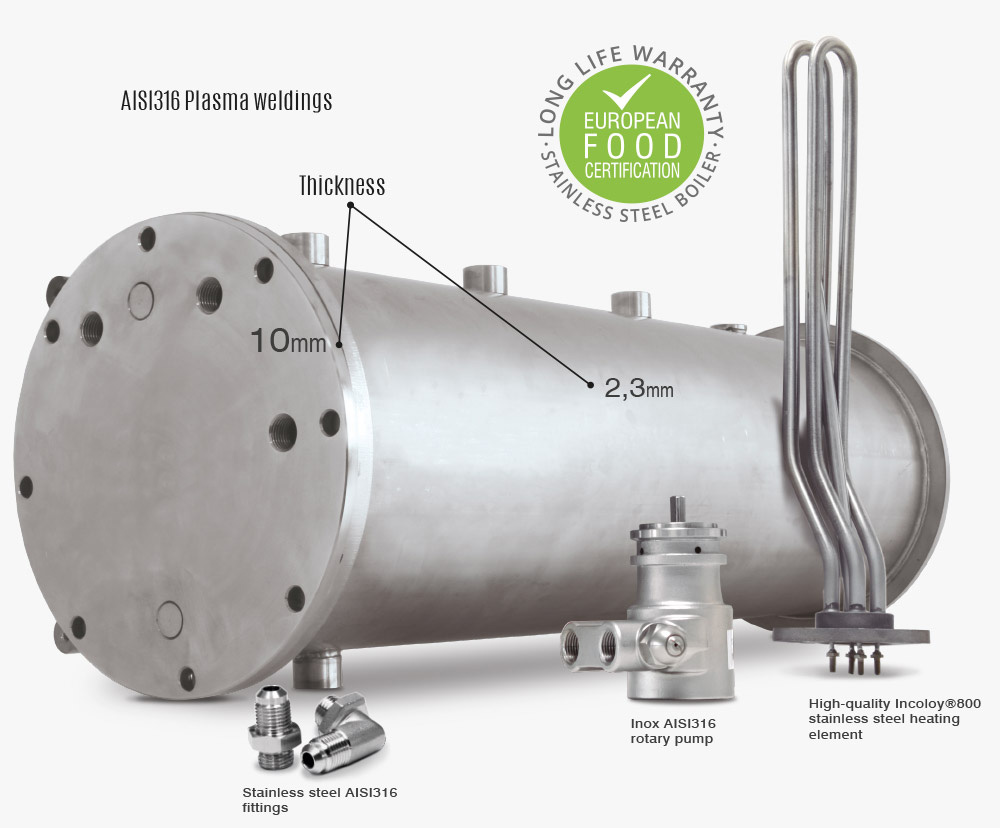

After the creation of our Big Dream model, in which we have changed a technical criterion used for more than 100 years (using stainless steel instead of copper and brass), we wanted to continue creating unique products. A product that would also mark a turning point in the industry.

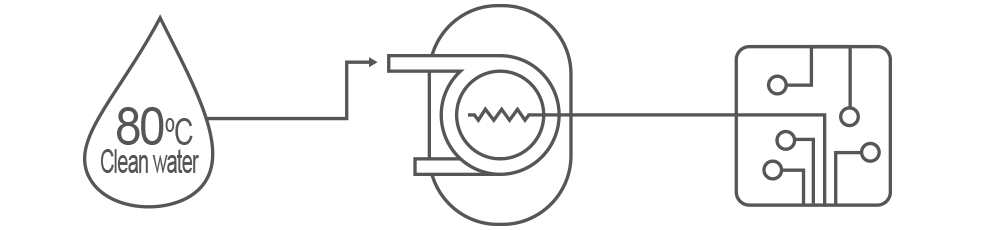

Technology T, is a state-of-the-art multi-group technology. Engineering developed entirely by Ascaso. It offers great thermal stability with a high level of energy efficiency (low energy consumption) and clean and fresh water in each coffee.

Benefits: