Home Pro

Professional PID (vibratory pump)

Professional PID (rotary pump)

Close/Cerrar

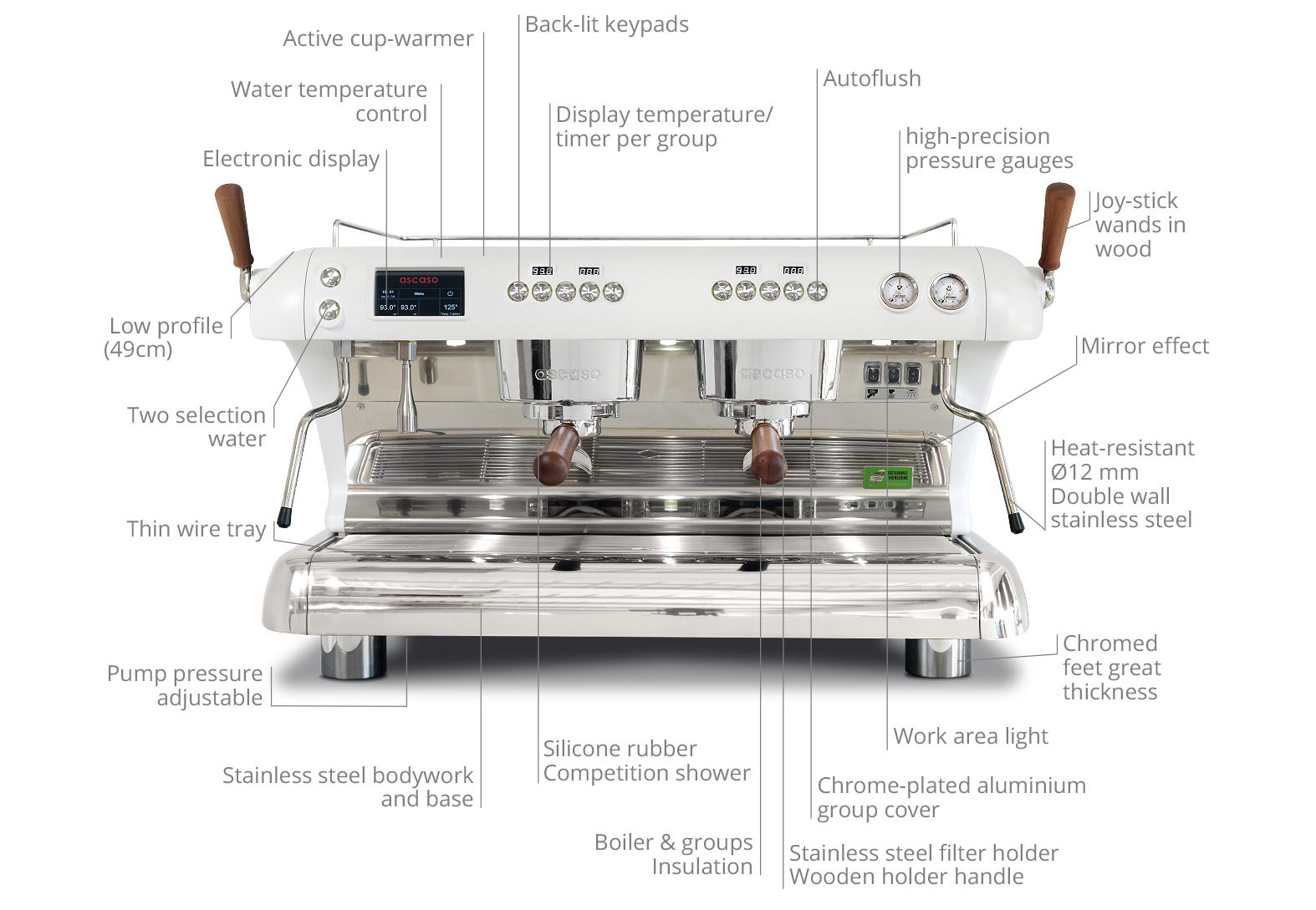

In the espresso world, when we talk about ergonomics we mean the optimization of the design of the coffee machine so the professional barista can work in the utmost comfort. Basically, what we are looking for is that the barista can perform his ‘choreography’ smoothly, comfortably and happily.

Based on structured data collection, we have designed our machine in line with the different ergonomic parameters demanded by baristas to ensure that their relationship with the Big Dream T is a joyous one. The essential elements have been devised and designed so that the creation of an espresso coffee and its specific choreography take place in the most comfortable possible circumstances for the professional barista.

We focused on various aspects of the handle:

Steam wands and water tubes in AISI 316 stainless steel

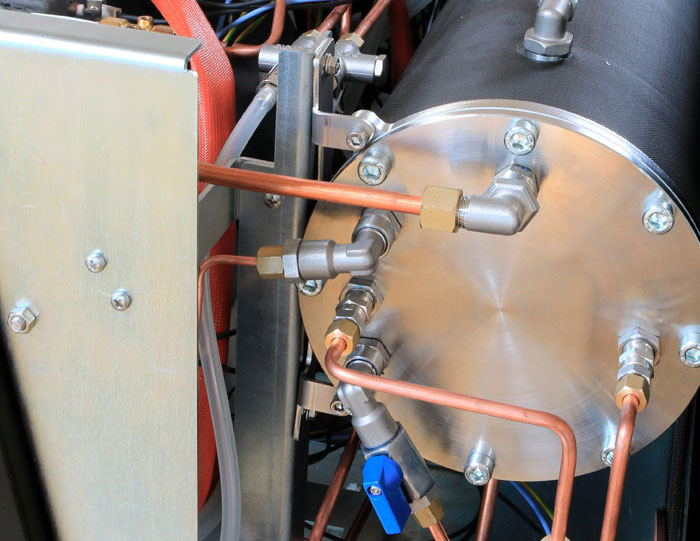

The machine has been designed primarily from the point of view of the barista, but we also took the technician’s perspective very much into account.

This is a nice product to repair! It is easy to dismantle with standard tools. It has very few screws and the components are easily accessible. There is plenty of space to carry out repairs with complete assurance.

This is a key factor to consider in a high quality product.

Good design presupposes that the product can be dismantled and repaired with ease. The idea is that it will last for years and years.

It is a matter of quality, productivity and also sustainability.

We have worked on this component by component.