Compact size

The compact size may hide the fact that the Dream boasts professional features that are normally reserved for larger machines: precise PID temperature control, high thermal stability, a cool-touch steam wand and, depending on the version, volumetric control, pull timer and an externally adjustable OPV valve.

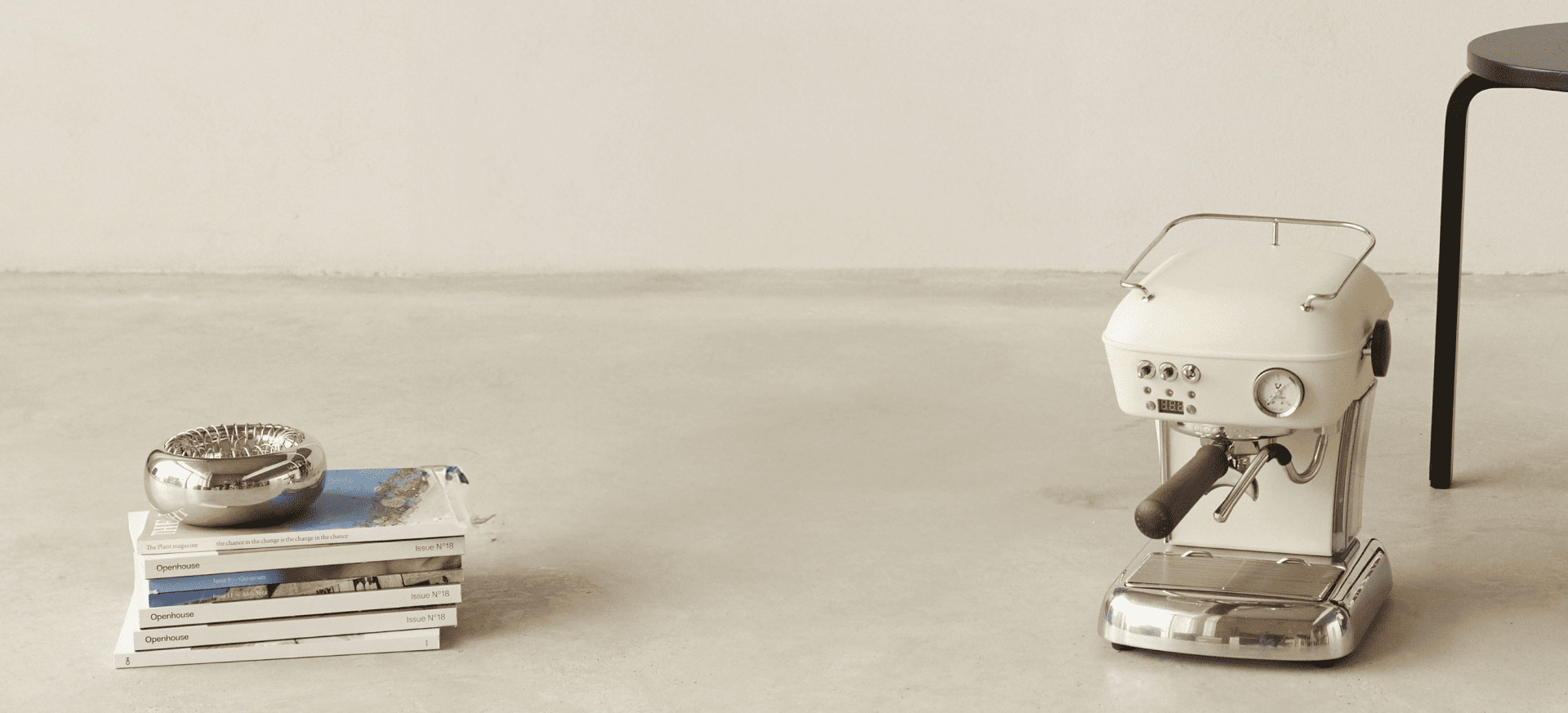

Distinctive design

Designed by Marc Aranyó in 2000, the Dream continues to embody a dreamlike essence. Without altering a single line of its striking silhouette, its retro aesthetics and its world full of color, it has evolved technologically to achieve the perfect cup at home. With its highly decorative design and vibrant colors, it remains an iconic symbol of innovation and style in the world of home coffee brewing.

Quality Commitment

Made from premium materials such as aluminum, stainless steel, and minimal plastic components, it embodies durability and sustainability. Its meticulously polished or painted aluminum body reflects artisanal craftsmanship, ensuring both functionality and aesthetic appeal.

Highlights

| Sheet | ||

|---|---|---|

|

|

|

| DREAM PID | DREAM ONE | |

| Pump | Vibratory | Vibratory |

| PID temperature control | via screen | Electronically |

| Digital Multifunction Display | ||

| Volumetric control | ||

| Extraction timer | ||

| Statistics | ||

| Programmable pre-infusion | ||

| Separate hot water | ||

| Thermal stability | ±1.5°C | ±1.5°C |

| Independent coffee and steam groups | ||

| Adjusting the Coffee Temperature | 80°C to 110°C in 1°C increments | 90 to 106°C in 2°C increments |

| Steam temperature adjustment | 110°C to 165°C in 1°C increments | 165°C |

| Water tank visible from the outside | 1.3 l (illuminated) | 1.3 l |

| Cool touch steam wand | 10mm stainless steel | 10mm stainless steel |

| Manometer | ||

| Externally adjustable overpressure valve | ||

| Backwash cleaning | ||

| Programmable standby | ||

| Insulated thermoblock | ||

| Active cup warmer | ||

| Work area lighting | ||

| Wooden handles | Walnut | |

| Housing material | aluminium | aluminium |

| Weight | 10 kg | 10 kg |

| Dimensions (W x H x D) | 245 x 345 x 280 mm | 245 x 345 x 280 mm |

| Power | 1100 W | 1050 W |

| Voltage | 230 V / 120 V | 230 V / 120 V |

| Accessories | ||

|---|---|---|

| DREAM PID | DREAM ONE | |

| Stainless steel portafilter with double nozzle | ||

| 7 gr stainless steel filter (1 coffee) | ||

| 14 gr stainless steel filter (2 coffees) | ||

| 18 gr stainless steel filter (2 coffees) | ||

| 7 gr pressurized filter (1 coffee) | ||

| 14 gr pressurized filter (2 coffees) | ||

| ESE Coffee Capsule Filter | ||

| Blind filter | ||

| Filter Holder Gasket | Gum | Gum |

| Stainless steel shower | Standard | Standard |

| Steam Tip | 1 hole | 1 hole |

| Tamper | Aluminium | Aluminium |

| Spoon | ||

| Shower brush |